By Shahid Yusuf

China’s Belt and Road Initiative (BRI) aims to create a Eurasian economic corridor and a string of economic hubs anchored to Chinese cities, thereby generating a development dynamic that is advantageous to China’s growth. The investment and trade generated by BRI could enable China to sustain a growth rate of 6 to 7 percent and double its GDP between 2010 and 2021. As of end 2016, $900 billion worth of BRI-related projects were planned or under implementation – with loans and credits from Chinese banks amounting to $1.2 trillion (not all for BRI projects). Chinese agencies claim that the BRI will eventually absorb between $4 trillion and $8 trillion.

But what are the benefits and risks for countries accepting BRI-linked financing to build transport and energy infrastructure?

To this day, the BRI remains a patchwork of projects without a well-articulated strategy backed by solid analysis of the potential benefits for China and countries that will borrow from Chinese entities to finance large infrastructure projects. This is critical if the politically less-than-stable countries in Central and South Asia with a poor track record of sound policymaking are to benefit from BRI. In order to service BRI loans, the investment in transport and energy infrastructures plus any associated technology transfer must attract private investment in tradable goods and services and increase export earnings from exports.[1] Whether such a virtuous spiral of investment and exports will ensue, is far from certain. Moreover, infrastructure building and mining on the scale envisaged could lead to severe environmental degradation absent the enforcement of strict regulations, which are either not in place or enforced with a light touch.

There are other reasons for proceeding cautiously down the Belt and Road. The terms and conditions of loans extended by Chinese entities are less than transparent. Furthermore, the governance and finances of the more than 50 Chinese state-owned enterprises that are responsible for major BRI projects are opaque, and their capacity to manage and implement complex transnational projects is untested. Contractual relations with such entities could prove to be tendentious if projects fail, the quality of work and materials is poor, or if lax environmental standards cause damage. The Tharparkar project in Pakistan is a case in point.

This context elicits the following questions and concerns that deserve closer attention and more systematic study.

Can China finance BRI projects to the tune of several trillion dollars from its own resources? And if not, will China need to tap the international bond market for the bulk of the financing? By doing so, its indebtedness would increase and it would absorb considerable risk associated with lending for long-term projects in countries such as Uzbekistan, Pakistan, Sri Lanka, and Laos. In the end, given the current state of China’s forex reserves, will the outlay on BRI be an affordable but not game changing $25 billion per year?

China’s neighbors worry that the purpose of BRI infrastructure and connectivity is to further Chinese exports and geopolitical ambitions. Many are already on the slippery slope to deindustrialization and BRI could accelerate the process. Existing light consumer manufacturing would be imperiled and the likelihood of diversifying into more complex products would be greatly diminished because of China’s competitive advantage in a wide range of manufactures.

European experience suggests that cross-border transport infrastructure has not led to regional convergence. If anything, it has tended to increase regional disparities by making existing hubs more dominant and disadvantaging nearby regions in the hubs’ shadow. Rail links between Milan and Naples have strengthened hub economies while contributing little to the development of Southern Italy. A study of road infrastructure building in Portugal came to similar negative conclusions: greater accessibility did not improve the cohesion and purchasing power of less developed parts of the country.

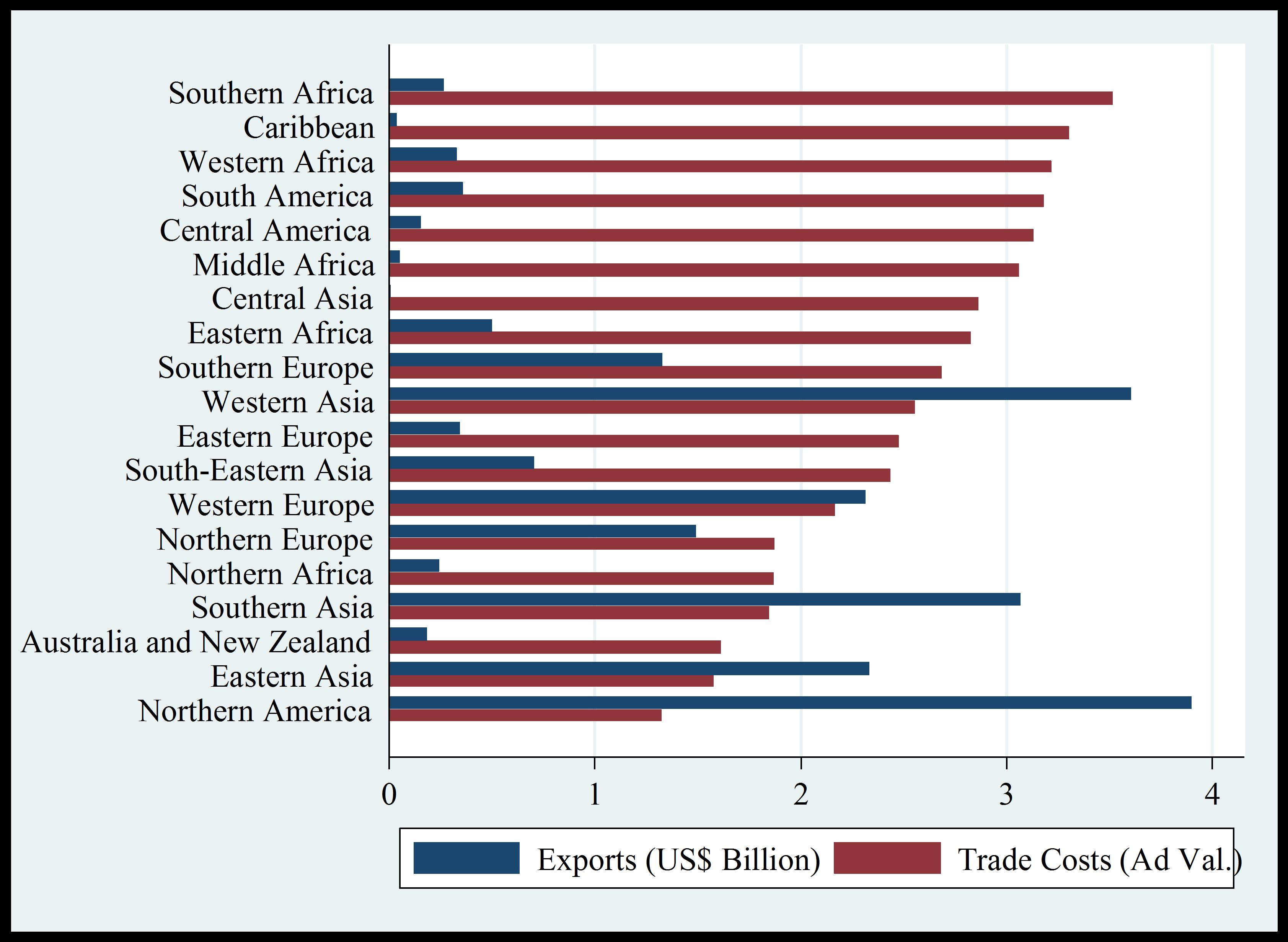

To service loans from China and other borrowers, countries on the receiving end of infrastructure investment will need to greatly expand their exports and run trade and current account surpluses. Given recent trends in manufacturing and slower growth of world merchandise trade, is that likely? In 2016, China ran a trade surplus amounting to $250 billion with participants in the BRI. Could countries such as Pakistan (which runs a $13 billion trade deficit with China) possibly narrow and reverse the trade gap and run surpluses with its hyper competitive neighbor?[2] If they do not, what is the return to these countries in the form of long term gains from infrastructure? In other words, how much growth could BRI projects unlock by way of tradable goods and services? Furthermore, if highly indebted countries are unable to repay these loans, what are the consequences for Chinese firms and for their bankers?[3] Taking over assets that will need to be marked down would involve absorbing large losses.

What is the risk of BRI exacerbating the resource curse in countries such as Kazakhstan, Turkmenistan, and Afghanistan? Could the creation of the BRI trade corridor render them even more resource dependent and stunt their non-resource based tradable sectors?

So far, China’s projects in its own Western provinces have at best yielded modest returns. The profitability of China’s foreign direct investment in developing countries has also been low. This suggests that the cross-national infrastructure projects intrinsic to BRI will be costly to build and the financial returns are likely to be meager, at least in the medium term. Political changes in destination countries could easily affect project outcomes. Political risk could discourage participation by investors from developed countries.

Geopolitical issues need to be factored in. China’s actions have alarmed some of its neighbors – India in particular.[4] Chinese closeness to and support for Pakistan could contribute to continuing friction between Pakistan and India. Political tensions within and among countries, sporadic violence (as in Pakistan’s Baluchistan Province), and arms races in South, Southeast, and East Asia may undermine the BRI – as will continuing discord in the Middle East. How might these developments and others affect growth prospects is a key question.

Shahid Yusuf is Chief Economist of the Growth Dialogue at George Washington University and an adjunct professor at Johns Hopkins University.

Note: The views expressed in this article are the author’s and do not necessarily represent those of Pakistan’s Growth Story.

[1] Premier Li Keqiang referred to technology transfer as China’s, “golden business card”. Financial Times (2017, July 18th p.9).

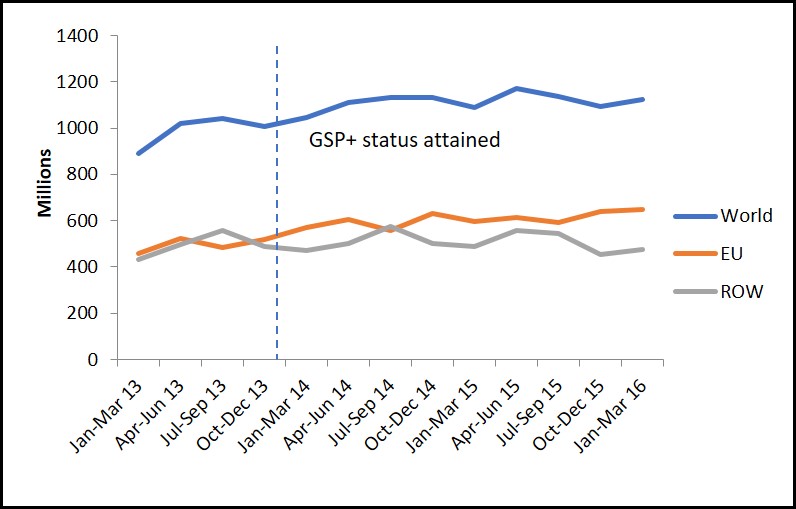

[2] Between 2006/7 and 2015/16, Pakistan’s exports to China went from $575 billion to $1.63 billion. Meanwhile China’s exports to Pakistan increased from $3.5 billion to $12.1 billion (Source: http://fp.brecorder.com/2017/03/20170314153866/). Figures in the Financial Times indicate that China’s exports amounted to $16.5 billion in 2015.

[3] Down the road, servicing the loans from China will be burdensome for many countries. Chinese firms have already encountered problems with projects in Myanmar, Sri Lanka and Indonesia. Chinese SOEs that are spearheading BRI, such as the China Railway Corporation, are themselves increasingly in debt to Chinese banks – CRC’s debts amount to $558 billion and these are rising largely because much of China’s 22,000 high-speed rail network runs at a loss (Source: https://www.ft.com/content/9a4aab54-624d-11e7-8814-0ac7eb84e5f1?mhq5j=e3, https://www.ft.com/content/156da902-354f-11e7-bce4-9023f8c0fd2e?mhq5j=e3).

[4] In response to BRI and disputes along its northern border with China have induced India to launch its own initiative extending from Africa to Southeast Asia variously called the “Spice Route” the “Blue Revolution” and SAGAR – “Security and Growth for all in the Region”. India is also investing $300 million to lease the 2,000 acre tract of land which is the site of the largely deserted Mattala Rajapaksa Airport adjacent to Hambantota Port in Sri Lanka in order to prevent a Chinese takeover of the facility and to control China’s access to the port that it has leased for 99 years (Source: http://www.businessinsider.com/india-and-china-are-fighting-for-control-in-sri-lanka-2017-12, https://www.reuters.com/article/us-sri-lanka-port-india/india-eyes-airport-in-sri-lanka-near-chinese-belt-and-road-outpost-idUSKBN1CI0KI).